- Expert Since 2013

- +918347947404

- ashaenterprise123@gmail.com

CO2 Gas System

1.DIRECT SYSTEM

Description

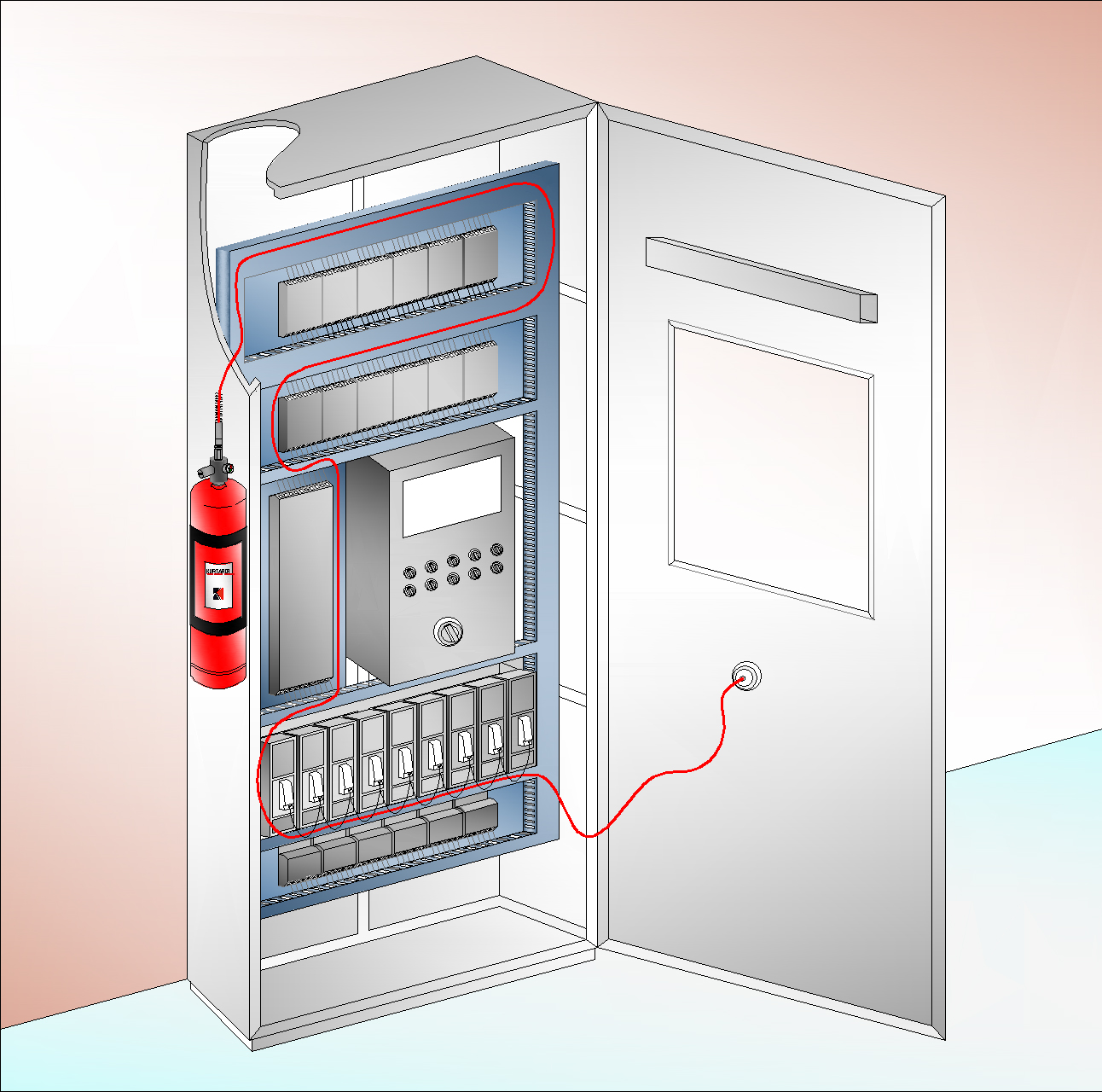

The ASHA Direct High Pressure System provides a simple and reliable fire protection solution for open and semi-enclosed server racks and electrical Cabinets. The Direct system utilizes pressurized polymer Detection Tubing as both a fire detecting sensor and extinguishment delivery device. The specialized tubing is leak resistant, flexible, durable and temperature Sensitive which allows it to quickly react when the heat from the fire is there and rupture will rupture when exposed to flame. The . The detection tubing connects to a custom engineered valve and a cylinder that contains the best fire suppression agent for a particular hazard.

The flexible red Detection Tubing can be routed throughout a server rack, Electrical panel ensuring detection and suppression of a fire right at its source. The tubing is designed to burst at the point of highest heat, forming an effective discharge. The ASHA Direct Systems are also ideal for protecting cable trays

One system can be configured to protect up to a total of 30-35 Meters of cabling. Direct systems can be fitted with an optional pressure switch to shut down electrical equipment or activate local or building alarms and integrated into the fire detection system.

THE PROBLEM

The risk of a fire is very real in today’s hot-running and overcrowded server racks and electrical closets. A minor server fire can cost a company significant financial loss.

THE SOLUTION

Our automatic fire detection and suppression are ideal for protecting server racks, control and electrical panels. We offer simple systems that are easy to install and can effectively provide round the clock protection.

Our systems use co2 fluid to provide quick and reliable detection and suppression system that will combat the fire and suppress it before it can spread to adjacent panels and racks.

ADVANTAGES

Fast, reliable fire protection without the damaging side-effects of water

Suppresses a fire in seconds, reducing equipment damage and downtime

Easy to install in any new or existing server rack or closet and requires no power to operate

Clean suppression agents require no post-discharge cleanup

Will not harm people, equipment or the environment

System options expand peripheral capabilities

Clean agents will not harm electronic equipment or magnetic media and also used on energized equipment

Does not interfere with installation or maintenance of equipment

2.INDIRECT SYSTEM

Description

ASHA ENTERPRISE is a specialized In-Cabinet Fire Suppression System, utilizing CO2 extinguishing agent.

ASHA ENTERPRISE In-cabinet suppression system is a fire suppression system designed for specific application of protecting electrical cabinets and enclosures.

In-Cabinet fire suppression systems are used because these are efficient as well as economical in protection of Computer Server cabinets, Electrical cabinets, CNC machines, IT closets, UPS switchgear cabinets,and archive storage enclosures to name a few. Rather than a total flooding of the whole room with an agent, only the specific cabinet is protected.

ASHA ENTERPRISE In-cabinet suppression system is a StandAlone Automatic Fire Suppression System. The effectiveness of a genuine HD ASHA ENTERPRISE System, happens by utilizing the best Fire Detection Tubing, which detects a fire due to precise temperature sensitivity, allowing our systems to react quickly and effectively.

This unique detection can be run through the smallest or most complex enclosures to ensure detection is always close at hand. ASHA ENTERPRISE System can be utilized anywhere that a fire poses a risk, and it is flexible enough for virtually any Industrial Equipment, Traditional as well as Emergency Vehicles, Storage Compartments, Control Cabinets or various types of Remote Installations From CNC Machines and Fume Hoods.

ASHA ENTERPRISE direct system quickly detects and suppresses fire, directly at the source, efficiently and automatically by discharging CO2. It is a totally self-contained, requiring external electric power and remains active and operational 24x7. After use, naturally-occurring element, CO2 dissipates into the air allowing easy usage. The CO2 discharge also leaves no residue, eliminating the need for agent cleanup and helping reduce downtime.CO2 is discharged through an indirect IHP Valve, which is a differential pressure piston valve that engages immediately when a fire is detected.

The Flexible Detection Tubing (FDT) provides protection in little difficult and hard to reach areas where other detection methods cannot be used. While a Rugged Detection Tubing can be used in harsh environments where other types of detection quickly deteriorate, rendering the system inoperable. While the Detection Tubing is at the heart of the system. By routing the tubing throughout a special hazard, the system can detect a fire at its source. The detection tubing is provided with an end of the line plug. This plug comes with or without an indicative gauge – indicating the pressure of CO2.

The system has an optional integrated weighing to give an indication and control over the amount of CO2 in the cylinder and ample time to replace the cylinder.

|

|

|

| |

|

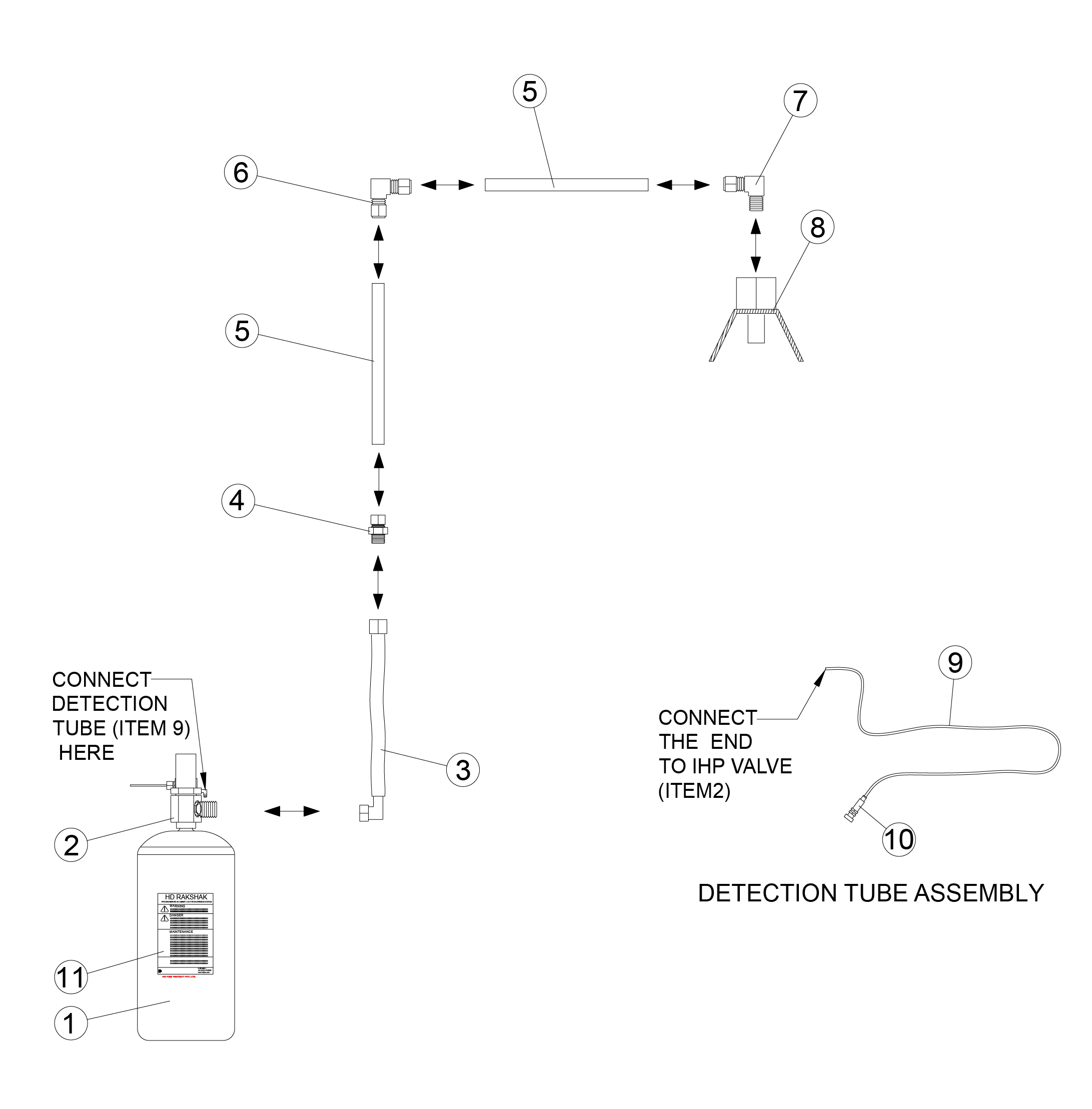

SYSTEM SCHEMATIC

PART LIST

| ITEM NO. | CODE NO. | DESCRIPTION | QTY |

|---|---|---|---|

| 1. | 119001 | CO2 CYLINDER - 2 KG | 1 |

| 119002 | CO2 CYLINDER - 4.5 KG | 1 | |

| 119003 | CO2 CYLINDER - 6.5 KG | 1 | |

| 119004 | CO2 CYLINDER - 9 KG | 1 | |

| 119004 | CO2 CYLINDER - 22.5 KG | 1 | |

| 119005 | CO2 CYLINDER - 45 KG | 1 | |

| 2. | 119008 | IHP-AUTOMATIC VALVE | 1 |

| 3. | 119026 | RUBBER HOSE PIPE | 1 |

| 4. | 119021 | MALE CONNECTOR (SS304) | 1 |

| 5. | 119007 | TUBE (SS304) | 2 |

| 6. | 119009 | ELBOW (SS304) | 1 |

| 7. | 119022 | ELBOW (SS304) | 1 |

| 8. | 119023 | NOZZLE WITH HORN | 1 |

| 9. | 119006 | HEAT DETECTION TUBE | 1 |

| 10. | 119028 | END OF LINE ADAPTOR WITH PRESSURE GAUGE | 1 |

| 11. | CNPR5998 | SELF ADHESIVE LABEL PVC, “HD-RAKSHAK “ | 1 |

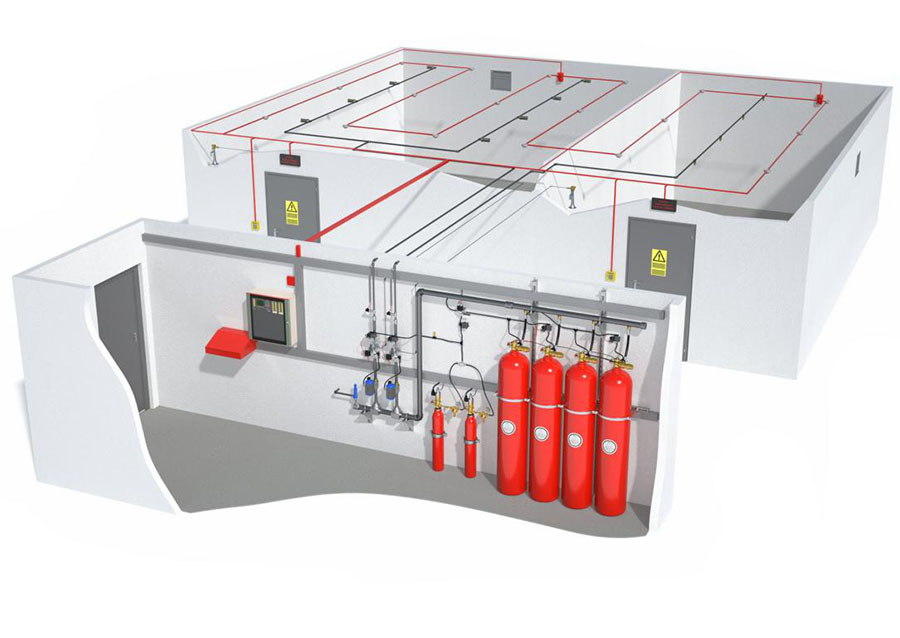

3. Co2 Flooding System

Description

Co2 is a colorless gas with a density about 60% higher than that of dry air. Considered as best extinguishing gas. It suppress oxygen by eliminating heat, co2 is most effective as a fire extinguishing agent NFPA-12 rules and BIS 6382 codes for design of such system are used as standard for co2 extinguishing or flooding system. Co2 gas generally stored in high pressure seamless steel cylinders is in liquid form with maximum filling ratio of 0.667 kg/ltr of cylinder volume. In order to the fire hazard co2 inders quantity varies. On large hazards where several cylinders are required a manifold is used to Detect each other by means of flexible hose and check valve.

The The cylinder's master valve is electronically operated and the slave valve is sure actuated. The master valve can be automaticall, or manually operated. Flow rate of co2 is controlled.

Note : Co2 Use in Unman area for total Flooding.

Application

| |

||||

|---|---|---|---|---|

| Electrical Panel | Electrical Room | Data Center | Server Room | Server Rack |

| Control Rooms | Transformer & Sub-station | Rolling Mills & Turbines | Powder Coating & Paint Booths | False Floors & Cable Shafts |