- Expert Since 2013

- +918347947404

- ashaenterprise123@gmail.com

Sliding Gate

Sliding Gate

Description

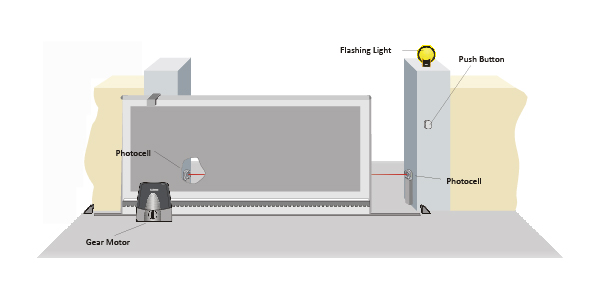

Sliding Gates are a mix of convenience and class. While there are many types of gates, this particular type uses a rack and pinion technology where the rack is moved by the gear motor by sliding the gate on the track which is made by toughened MS. When the question about the size of gate that can be automated, you can be assured that any gate weighing between 200 to 4000kg can be automated.

The main part of an automated sliding gate is its gate motor. These gate motors come in two different variants - AC and DC. The major difference is that DC motors are used for small gates with battery backup and solar power, whereas AC motors are used in gates that are on the heavier side for its might and durability. To tackle the issue of a power failure, our motors are equipped with a manual mode function – meaning, it can operate even in case of a power failure. All the motors are with non-reversible gear box which helps in locking the gate even without a drop bolt or any kind of lock.

To avoid any type of accident, we’ve made these gates smart! These motors are intelligent enough to track any obstacle and stop whenever it detects anything on its way, preventing any kind of physical damage to man or machine. Since the gear box is oil based, the operation is absolutely silent and protected by a thermal switch to safeguard, it in case of any overheating. The advance electronic control unit permits opening time adjustment, partial opening, automatic closing, step by step control, stop safety, reverse safety etc.

Features

Cantilever track and pair of bottom trolley rollers are manufactured using imported make

No need to push manually as electric devices enable auto-open and close functions

Use of top nylon guide rollers with bearing ensuring smooth operations

Also available with inbuilt hinged/sliding type for comfortable pedestrian use

Sliding gates can also be operated manually in case of power failure

Separate control is provided to stop gate anytime while moving

High quality CNC finish top and bottom rollers

Use of latest technology for automation and energy efficiency

Space saving design adjustable to any structural situation

Cost efficient and

low maintenance

Use of High Grade Steel to make all components of sliding gate

Installed with reverse

motion mechanism

Easy to install on unsterilized floor or perfectly horizontal

| Electromechanical actuator | For Sliding Gates upto 1500 kg | For Sliding Gates upto 4000 kg |

|---|---|---|

| Travel control system | Encoder limit stop | magnetic mechanical stop |

| Capacity | 1500 kg | 4000 kg |

| Duty class | Intensive | Very heavy duty |

| Intermittent | 70% | S1 = 100% |

| Power supply | 230V ~ / 50Hz | 230V ~ / 50Hz |

| Input | 200 W | 3 A |

| Thrust / Torque | 74 Nm | 100 Nm |

| Opening speed | 0.16 m/s | 0.29 m/s |

| Closing speed | 0.16 m/s | 0.29 m/s |

| Release system | key operated | key operated |

| Operating | -20°C / +55°C | -20°C / +55°C |

| Protection rating | IP 44 | IP 44 |

Maintenance

Description

It’s important to properly maintain your automated gate to keep it working properly over a long period. The gate is a mechanical device and will more effectively protect your commercial or residential property when you take care of it consistently. Here are five tips that will make sure your automated gate lasts a long time.

Inspections SMake sure all bolts are held in place and tightly screwed. Do you notice any holding cables or springs being held in place by loose bolts? Don’t try to fix these items on your own. You might break them. Call in a qualified technician instead. |

You should use a lubricant recommended by the manufacturer every six months on all-important gate parts. Pay close attention to all system parts that help keep your gate moving properly, such as: • Pulleys • Chains • Hinges • Rollers • Screws |

One of the best ways to keep your automated gate looking new and fresh for long periods is to wash it on an annual basis. Wax it after it’s cleaned. If you have a wooden gate, then apply new paint once per year. |

• Tarnished • Rusted • Faded . |

| |

||||||

|---|---|---|---|---|---|---|

| It park | Hospital | Commercial building | Government office | |||

| Shooping mall | Factories | Housing | Apartments | |||